Custom RFID Metal Tag Supplier

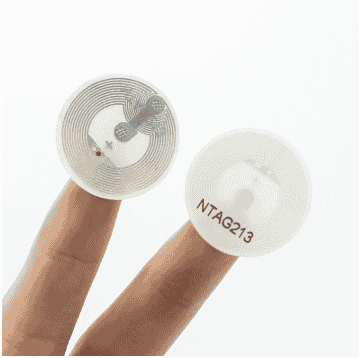

RFID Metal Tags also called Anti-metal RFID tags which are specifically designed for use on metal surfaces or environments where standard RFID tags fail due to interference. Common types include flexible labels, hard tags, and on-metal stickers, available in HF, NFC, and UHF frequencies. Popular chips include MIFARE Classic, NTAG213, and Alien H3. UCODE 8 ,These tags are widely used in asset tracking, equipment management, logistics, and industrial automation.

They are durable construction ensures reliable performance in harsh conditions, making them ideal for use on machinery, IT equipment, vehicles, and metal containers. Anti-metal RFID tags provide efficient identification and data management on metallic surfaces.

Contact us to get Professional advice for your RFID Metal Tag needs.

15 FAQs About Anti-Metal RFID Tags

1. What are anti-metal RFID tags?

Anti-metal RFID tags are specially designed tags that work efficiently on metal surfaces or in environments where metal interferes with standard RFID performance.

2. How do anti-metal RFID tags work?

They use a special insulating layer or material to prevent interference caused by metal surfaces, ensuring proper signal transmission.

3. What types of anti-metal RFID tags are available?

Common types include flexible on-metal labels, hard tags, ceramic tags, and rugged industrial tags.

4. What frequencies do anti-metal RFID tags use?

They are available in HF (13.56 MHz), NFC, and UHF (860-960 MHz) frequencies, depending on the application.

5. What chips are used in anti-metal RFID tags?

Popular chips include MIFARE Classic, NTAG213 (NFC), Alien H3 (UHF), and Impinj Monza series for UHF applications.

6. Where are anti-metal RFID tags commonly used?

They are used in asset tracking, industrial automation, IT equipment management, vehicle tracking, and metal container identification.

7. Are anti-metal RFID tags waterproof?

Many anti-metal RFID tags, especially hard tags and rugged ones, are waterproof and resistant to harsh conditions.

8. Can anti-metal RFID tags be customized?

Yes, they can be customized in size, shape, chip type, and printed with logos, barcodes, or serial numbers.

9. What is the read range of anti-metal RFID tags?

The range varies by frequency and tag type. HF/NFC tags have a range of a few centimeters, while UHF tags can reach several meters.

10. Are anti-metal RFID tags reusable?

Yes, they are reusable and durable, especially hard tags and ceramic tags, which are designed for long-term use.

11. What industries benefit from anti-metal RFID tags?

Industries such as logistics, manufacturing, automotive, IT, healthcare, and oil and gas commonly use these tags.

12. Can anti-metal RFID tags withstand harsh environments?

Yes, many are designed to be heat-resistant, waterproof, and durable for use in rugged or outdoor environments.

13. How are anti-metal RFID tags attached to surfaces?

They can be attached using adhesives, screws, rivets, or magnets, depending on the tag type and application.

14. What is the lifespan of an anti-metal RFID tag?

The lifespan varies, but rugged hard tags can last for years, even in harsh conditions.

15. What are the advantages of anti-metal RFID tags?

They enable reliable tracking and data management on metal surfaces, provide high durability, and function in environments where standard RFID tags fail.

7 Common Application Scenarios of Anti-Metal RFID Tags

1. Asset Tracking in IT Equipment

Material: Hard tag or flexible label

Chip: Alien H3 (UHF) or MIFARE Classic (HF)

Advantages: Reliable identification of metal IT assets (servers, laptops). Durable for long-term use.

Disadvantages: Hard tags may be bulky for smaller devices.

2. Industrial Equipment Management

Material: Rugged hard tags

Chip: Impinj Monza R6-P (UHF)

Advantages: Withstands harsh environments, including heat and moisture. Ideal for heavy machinery and tools.

Disadvantages: Higher cost compared to standard RFID tags.

3. Logistics and Metal Container Tracking

Material: Flexible on-metal labels or ceramic tags

Chip: Alien H3 (UHF)

Advantages: Long read range for efficient tracking in warehouses or shipping. Easy adhesion to containers.

Disadvantages: Adhesive labels may wear out in extreme outdoor conditions.

4. Vehicle Tracking and Maintenance

Material: Hard or rugged ceramic tags

Chip: Impinj Monza 4QT (UHF)

Advantages: Tracks vehicles during production or maintenance. Resistant to impact and temperature changes.

Disadvantages: Installation may require screws or rivets, making it time-consuming.

5. Oil and Gas Industry Pipeline Monitoring

Material: Ceramic anti-metal tags

Chip: Alien H3 (UHF)

Advantages: High durability for extreme environments like oil rigs or pipelines. Reliable signal despite metallic surroundings.

Disadvantages: High cost and specialized mounting required.

6. Medical Equipment Management

Material: Small ceramic or flexible tags

Chip: NTAG213 (NFC) or MIFARE Ultralight

Advantages: Enables quick scanning and inventory management of metallic medical instruments. Compact size.

Disadvantages: Limited read range for NFC chips.

7. Retail and Supply Chain Inventory

Material: Flexible on-metal labels

Chip: Impinj Monza R6 (UHF)

Advantages: Tracks metal goods (e.g., appliances) in retail or warehouses. Easy to attach and cost-effective for large-scale use.

Disadvantages: Adhesive backing may degrade in outdoor use.

Each type of anti-metal RFID tag is optimized for its application, with trade-offs between durability, cost, and functionality.