RFID Laundry Tag Supplier

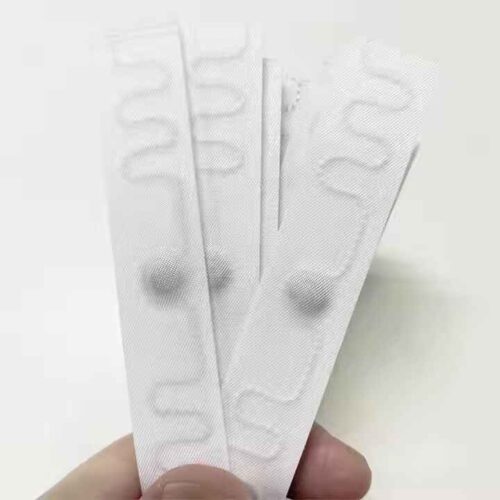

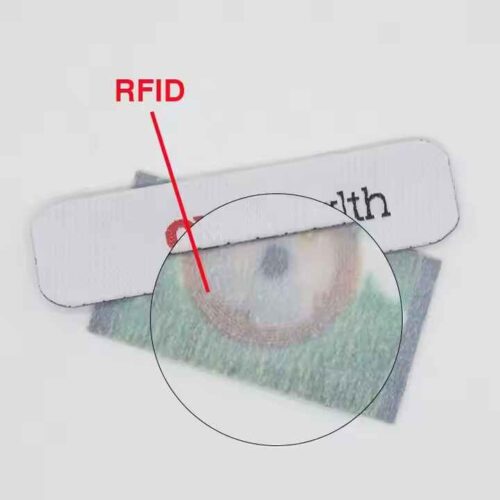

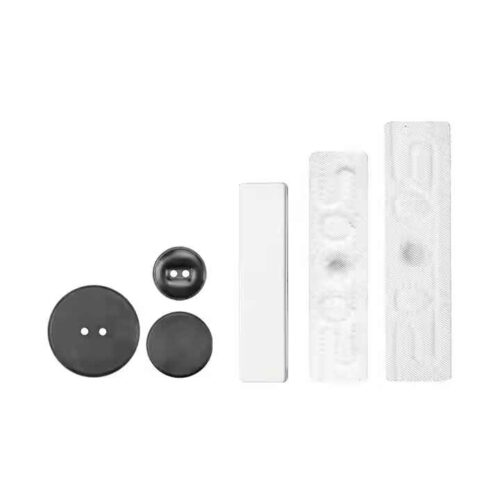

RFID Laundry Tags are durable, waterproof RFID tags designed for use in textile and garment management. Made from materials like PPS, silicone, or polyester, they can withstand high temperatures, chemical exposure, and repeated washing cycles. These tags typically use chips such as NXP UCODE (UHF) or ICODE SLIX (HF) and operate at Ultra High Frequency (860-960 MHz) or High Frequency (13.56 MHz).

Applications include tracking uniforms, hotel linens, hospital textiles, and industrial laundry, ensuring efficient inventory management, reducing losses, and streamlining sorting and handling processes.

We are a professional Laundry Tag manufacturer from China ,Custom you Laundry Tag with affordable price.

### RFID Laundry Tag FAQ

- What materials are RFID laundry tags made of?

RFID laundry tags are made from durable materials like PPS, silicone, or polyester, designed to withstand high temperatures, chemicals, and mechanical stress.

- What type of chips are used in RFID laundry tags?

Common chips include NXP UCODE (UHF) and ICODE SLIX (HF), which provide reliable performance for textile tracking.

- What frequencies do RFID laundry tags operate on?

RFID laundry tags operate on:

– High Frequency (HF): 13.56 MHz

– Ultra High Frequency (UHF): 860-960 MHz

- What is the read range of RFID laundry tags?

– HF tags: Up to 1 meter

– UHF tags: Up to 5-7 meters (depending on the reader and environment).

- Can RFID laundry tags survive washing and drying cycles?

Yes, RFID laundry tags are designed to handle industrial laundry processes, including washing, drying, ironing, and sterilization.

- Are RFID laundry tags waterproof?

Yes, RFID laundry tags are fully waterproof and can endure prolonged exposure to water and detergents.

- What are the typical applications of RFID laundry tags?

Applications include textile inventory management, uniform tracking, hotel linen management, hospital laundry tracking, and industrial laundry services.

- Can RFID laundry tags be sewn into garments?

Yes, RFID laundry tags can be sewn, heat-sealed, or embedded in garments and textiles, depending on the design.

- What is the lifespan of an RFID laundry tag?

Most RFID laundry tags last for 200-300 washing cycles or more, depending on the material and usage conditions.

- What is the production lead time for RFID laundry tags?

Production and delivery typically take 2-4 weeks for standard or custom RFID laundry tags, depending on order quantity and specifications.

- Can RFID laundry tags be customized?

Yes, tags can be customized in terms of size, shape, printing (logos or barcodes), and chip selection to meet specific needs.

- How do RFID laundry tags improve efficiency?

RFID laundry tags enable automated sorting, inventory tracking, and usage monitoring, reducing manual errors and labor costs.

- Are RFID laundry tags safe for sensitive fabrics?

Yes, RFID laundry tags are designed to be lightweight and flexible, making them safe for most fabrics, including delicate ones.

- What is the minimum order quantity (MOQ) for RFID laundry tags?

The MOQ varies by supplier but is typically around 500 to 1,000 tags for custom orders.

- What is the cost of RFID laundry tags?

The cost depends on the chip type, material, customization, and order quantity, ranging from $0.50 to $2.00 per tag for bulk orders.

### Laundry Tags: Evolution and Future Prospects

RFID laundry tags have revolutionized textile and garment management, enabling businesses to streamline operations and reduce losses. These specialized RFID tags are designed to endure extreme conditions, including high temperatures, water exposure, and harsh chemicals, making them ideal for industrial laundry processes. Over the years, RFID laundry tags have evolved significantly, offering improved durability, performance, and versatility.

In the early stages, RFID technology in laundry management was limited by cost and durability. However, advancements in materials like PPS, silicone, and polyester, combined with the development of robust chips like NXP UCODE (UHF) and ICODE SLIX (HF), have made RFID laundry tags more reliable and cost-effective. These tags now offer extended lifespans, withstanding hundreds of washing, drying, and ironing cycles. The ability to track individual items has brought immense benefits to industries like hospitality, healthcare, and industrial laundries, where tracking linens, uniforms, and garments is critical.

The adoption of RFID laundry tags has transformed operations in these industries. Automated inventory management and sorting systems eliminate manual errors, save time, and reduce labor costs. In hospitals, RFID tags ensure accurate tracking of patient gowns and linens, while in hotels, they help monitor and manage large volumes of towels and beddings. For industrial laundries, RFID tags provide insights into usage patterns, helping extend the life of textiles and optimize resource allocation.

Looking to the future, the RFID tag market is expected to grow as the technology becomes more affordable and accessible. Innovations in chip designs and tag miniaturization will allow for even more seamless integration into textiles. Additionally, the integration of RFID with IoT (Internet of Things) platforms will enable real-time monitoring and advanced analytics, further improving efficiency and sustainability. As businesses increasingly prioritize efficiency, sustainability, and data-driven decision-making, RFID laundry tags will play a pivotal role in shaping the future of textile and garment management.

In conclusion, RFID laundry tags have come a long way, and their potential is far from exhausted. With ongoing advancements in technology, they are set to become an indispensable tool for industries worldwide.