Description

RFID Tire Tag

The RFID Tire Tag is a specialized RFID tag designed for seamless integration into tires for tracking, identification, and lifecycle management. Built with durable materials to withstand the harsh conditions inside a tire, this tag is embedded during the manufacturing process or retrofitted onto existing tires. Operating at UHF (860-960 MHz) frequencies, the RFID Tire Tag provides reliable performance, enabling efficient monitoring of tire usage, maintenance, and inventory.

With a unique identification code stored in each tag, businesses can track tires throughout their entire lifecycle—from production to disposal. The tags are engineered to endure the extreme heat, pressure, and constant motion that tires experience during operation. Additionally, they ensure real-time data collection and integration with automated systems, enhancing traceability and operational efficiency in industries such as automotive, fleet management, logistics, and aviation.

Key Features:

-

- Durable and Heat-Resistant Design:

- Constructed with high-temperature-resistant materials to withstand the harsh conditions inside a tire.

- Resistant to heat, pressure, vibration, and deformation.

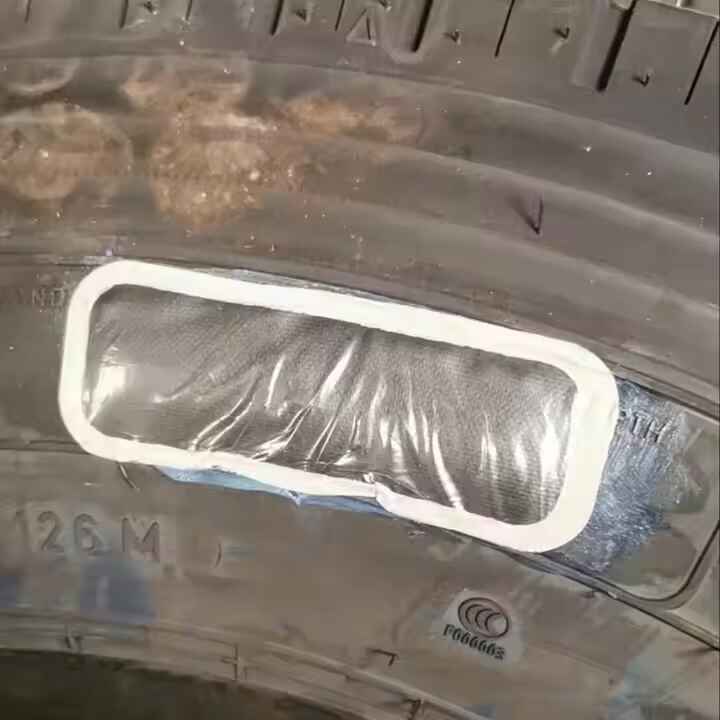

- Seamless Integration:

- Can be embedded during tire manufacturing or affixed to existing tires using specialized adhesives or mounting techniques.

- Does not affect tire performance or safety.

- Unique Identification:

- Each tag stores a unique serial number, enabling precise tracking and identification for each tire.

- Prevents counterfeiting and ensures traceability.

- Lifecycle Management:

- Tracks tires from production to usage, maintenance, and disposal.

- Enables efficient monitoring of tire wear, pressure, and performance history.

- High Performance:

- Operates in UHF (860-960 MHz) frequency ranges for varied applications.

- Provides reliable read/write capabilities even in high-speed environments.

- Automation and Efficiency:

- Seamlessly integrates with automated systems for tire inventory management, fleet tracking, and maintenance scheduling.

- Reduces manual processes and improves data accuracy.

- Environmentally Resistant:

- Designed to function in extreme environmental conditions, including high temperatures, humidity, and exposure to chemicals.

Applications:

- Fleet Management:

- Monitor tire usage, wear, and replacement schedules for trucks, buses, and other fleet vehicles.

- Tire Manufacturing:

- Enhance quality control and traceability during the production process.

- Logistics and Warehousing:

- Track tire inventory and ensure proper stock management.

- Aviation:

- Monitor aircraft tire performance and history for safety and maintenance compliance.

- Automotive Aftermarket:

- Enable tracking and management of replacement tires in retail and service centers.