RFID Jewelry Inventory Management is transforming how jewelry brands control, protect, and scale their operations. In an industry defined by high-value products, complex SKUs, and frequent item movement, traditional inventory methods are no longer sufficient.

Manual counting, barcode scanning, and spreadsheet-based tracking often result in inaccurate stock data, time-consuming audits, and increased risk of loss. RFID technology offers a smarter, automated alternative—bringing real-time visibility and precision to every jewelry item.

Why RFID Jewelry Inventory Management Is Essential Today

Jewelry inventory presents unique challenges. Items are small, valuable, and frequently handled by staff and customers. Even minor inaccuracies can lead to revenue loss or customer dissatisfaction.

With RFID jewelry inventory management, each piece is tagged with a unique RFID identifier, enabling non-line-of-sight scanning and instant data capture. This allows businesses to monitor inventory movement across warehouses, stores, showcases, and sales counters in real time.

Key advantages include:

-

Real-time jewelry inventory visibility

-

Inventory accuracy above 99%

-

Faster stock audits with handheld RFID readers

-

Reduced shrinkage and misplacement

-

Improved staff efficiency and customer service

According to industry research from GS1 and RAIN RFID Alliance, RFID adoption in retail significantly improves inventory accuracy and operational efficiency (DoFollow external references recommended).

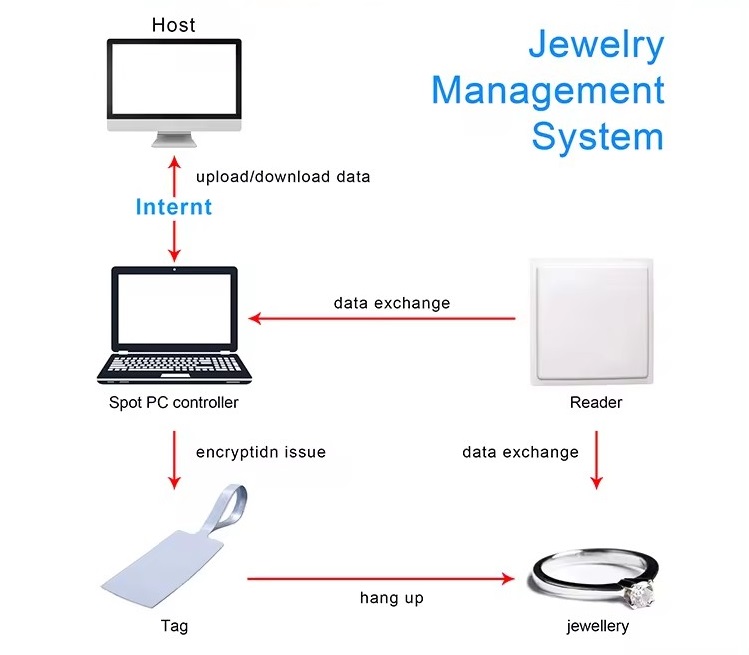

How an RFID Jewelry Inventory Management System Works

An RFID-based jewelry inventory management system typically includes:

-

RFID jewelry tags designed for metal environments

-

Handheld and fixed RFID readers

-

Inventory management software integrated with ERP or POS systems

Each jewelry item is digitally associated with its RFID tag. When items are moved, displayed, sold, or returned, the system automatically records the action—eliminating manual input and human error.

This creates a real-time, data-driven jewelry stock management system that supports smarter purchasing, merchandising, and loss prevention strategies.

Case Study: Glomax’s RFID Jewelry Inventory Management Application

Glomax recently implemented an RFID jewelry inventory management solution for a growing jewelry retailer operating multiple counters and a centralized warehouse.

The Client’s Challenges

Before RFID deployment, the client faced:

-

Long inventory cycles requiring after-hours labor

-

Frequent discrepancies between physical and system stock

-

Limited traceability of individual jewelry pieces

-

Operational stress during peak sales seasons

The RFID Solution by Glomax

Glomax provided a customized RFID inventory solution for jewelry, including:

-

High-performance RFID jewelry tags optimized for precious metals

-

Handheld RFID readers for fast daily and monthly audits

-

Software integration with the client’s existing ERP system

Staff training ensured smooth adoption without disrupting daily operations.

Measurable Results After RFID Implementation

Within the first month, the client achieved:

-

Over 80% reduction in inventory counting time

-

Near real-time visibility across all locations

-

Dramatic reduction in missing and misplaced items

-

Improved confidence among sales staff during customer interactions

Most importantly, management gained actionable insights into jewelry movement and sales patterns—turning inventory data into a strategic asset.

RFID Jewelry Inventory Management as a Long-Term Strategy

RFID jewelry inventory management is no longer just a technology upgrade—it is a competitive advantage. As jewelry brands scale, RFID enables control, transparency, and trust across the entire supply chain.

At Glomax, we help jewelry businesses move beyond basic tracking and into intelligent, secure, and scalable inventory management.